The majority of sensors on the measurement masts detect environmental influences. Primarily, of course, wind speeds, but also temperature, humidity and solar irradiance. Together with the LiDAR devices in the field and on the wind turbines, it is possible to detect turbulent wind fields that will hit the wind turbine rotor in the next few seconds. When the wind field hits the rotor, the individual blades react quite differently – depending on the turbulence. The blades flex and move. In order to detect this flexing with millimetre precision, each blade is equipped with a wide variety of sensors. Flexing can be determined mechanically (stain gauges) or optically (fibre optic extensometers). The exact movement of the blade is recorded by numerous acceleration sensors. A network of piezoelectric sensors detects possible damage or overloading of the rotor blade at an early stage. In simple terms, this structural health monitoring allows the researchers to see at an early stage how the material is performing and when it is the optimum time to replace individual parts or materials.

The forces on the rotor blades are transmitted via the blade bearings to the hub and drive the generator. Not only the blade bearings, but also the azimuth and main bearings are closely monitored to reliably detect these forces. The electrical components of the generator, converter and transformer are also comprehensively instrumented in order to monitor the behaviour of the various subsystems while taking into consideration all factors and thus allow predictions to be made about their service life.

The largest component of a wind turbine, the tower, is also exposed to very strong forces. Acceleration and strain sensors make it possible to detect and analyse even the smallest movement of the tower. The instrumentation extends all the way down into the foundations. The foundation piles transfer all the forces acting on the wind turbine into the ground.

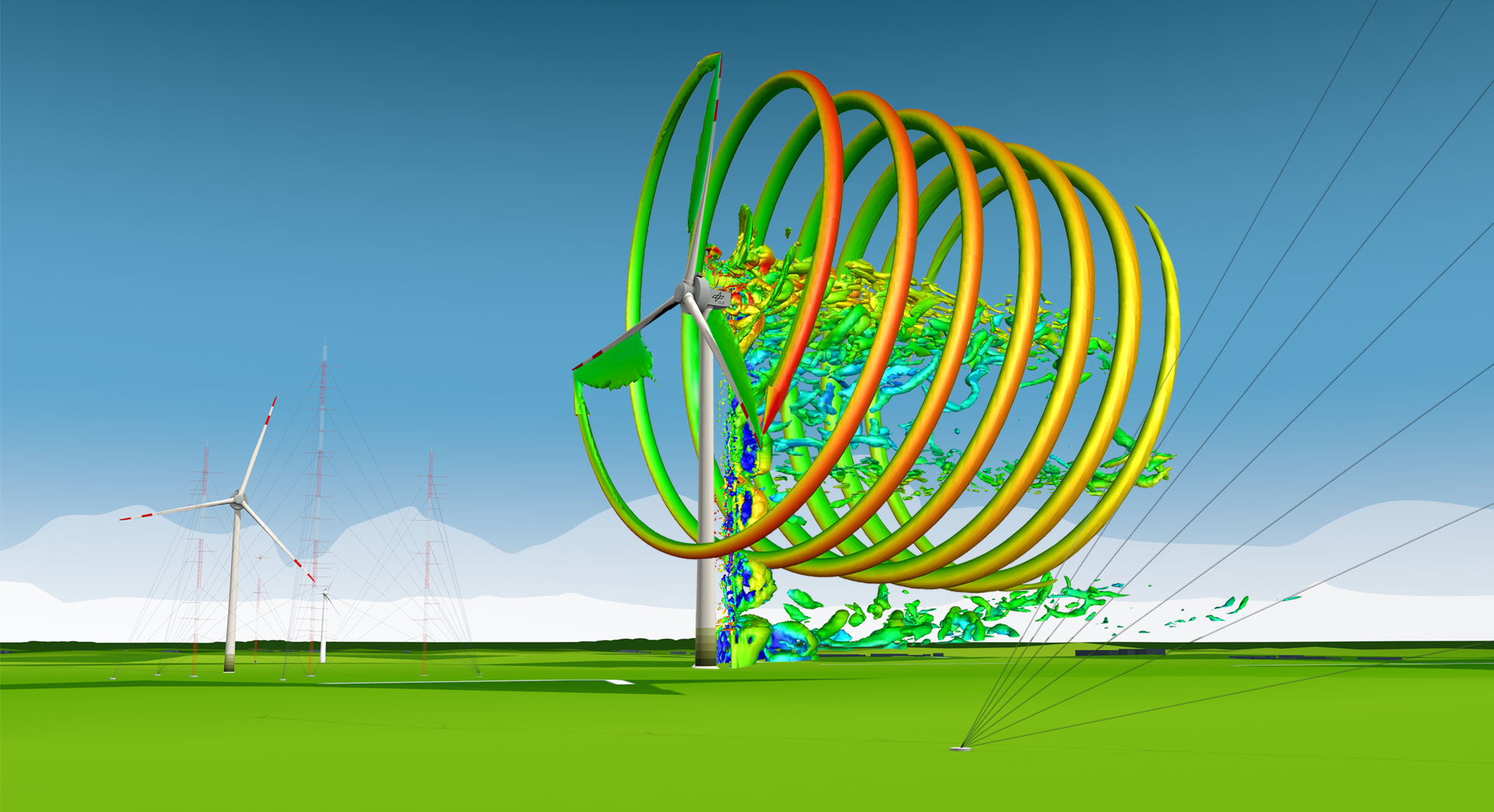

In addition to discharging loads into the ground, the rotor also changes the wind field (strength, turbulence, noise) behind the turbine. These effects are recorded by the sensors on the measurement masts (dependent on the wind direction) and can be analysed in real time.

The multitude of sensors continuously generate a very large volume of data, which is available to the scientists at any time and any place thanks to a sophisticated data management system.